World's cheap and best Home Constructing Technique towards you now.

Price: Rs 3.27 Lakh

with Pan Mixer

First time in India.

Are you a builder, Government contractor, Civil engineer or Architect?

Start bricks production on your construction site, and save Rs.4/- per brick.

( Save 70% bricks construction cost )

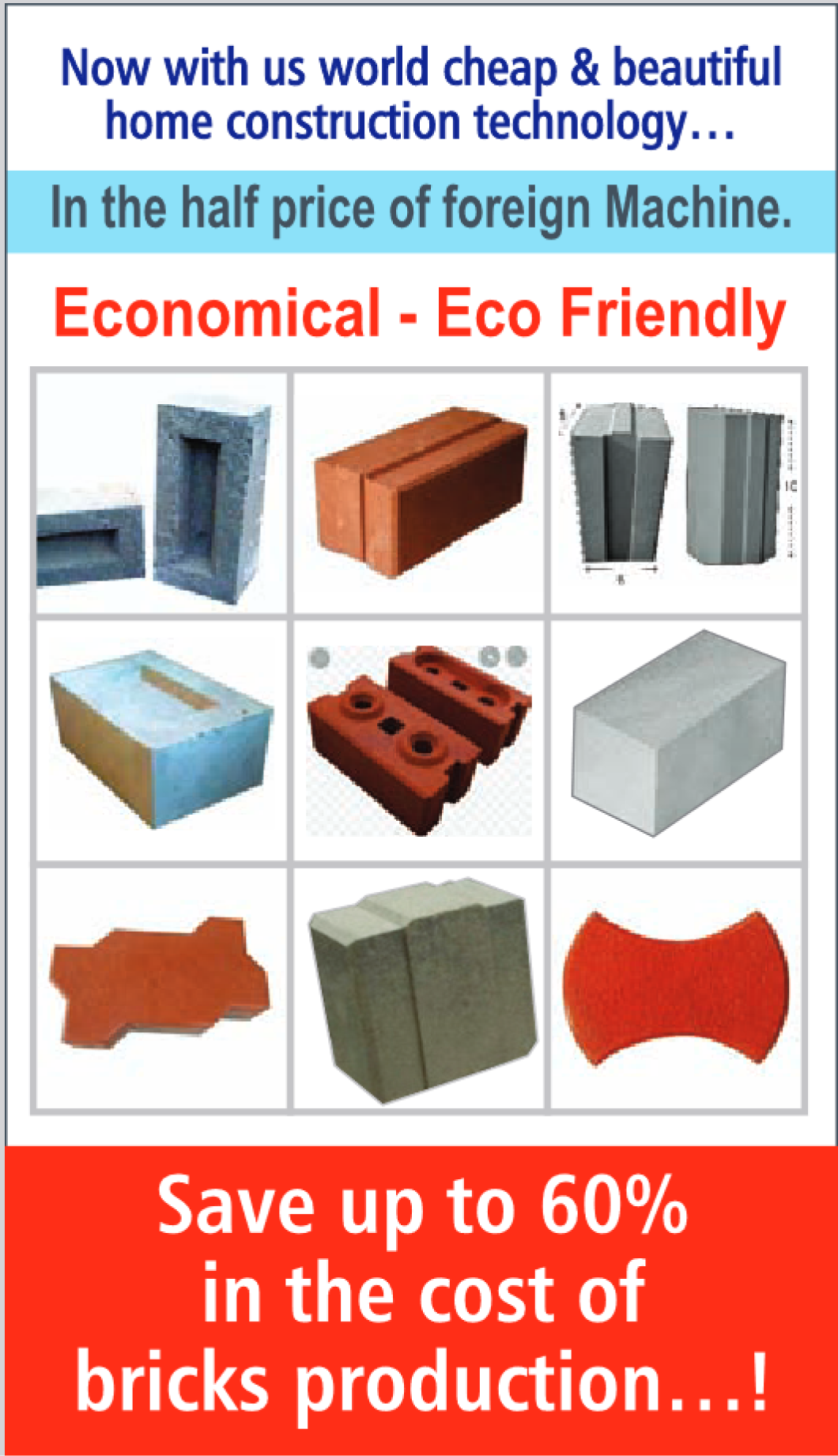

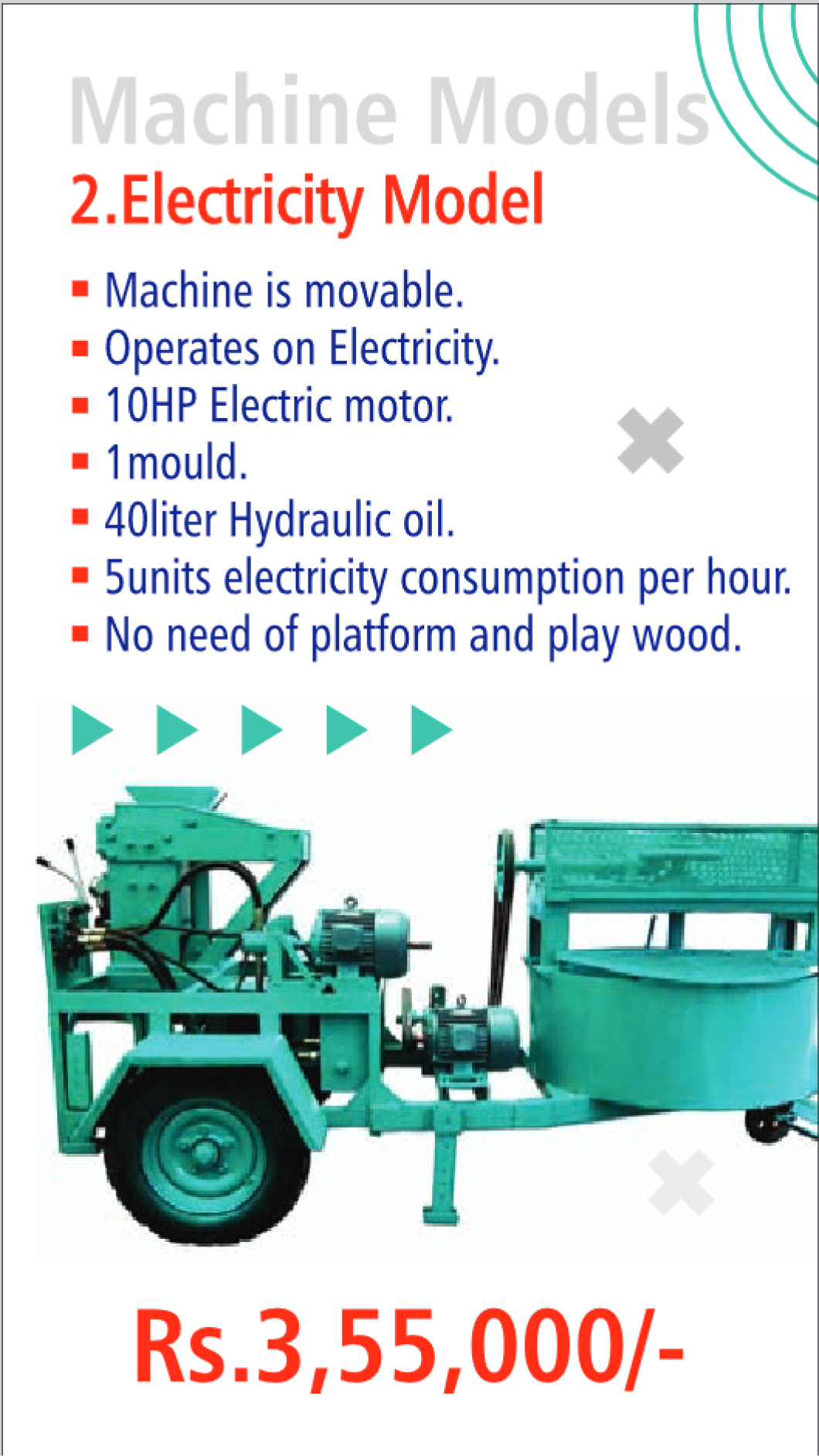

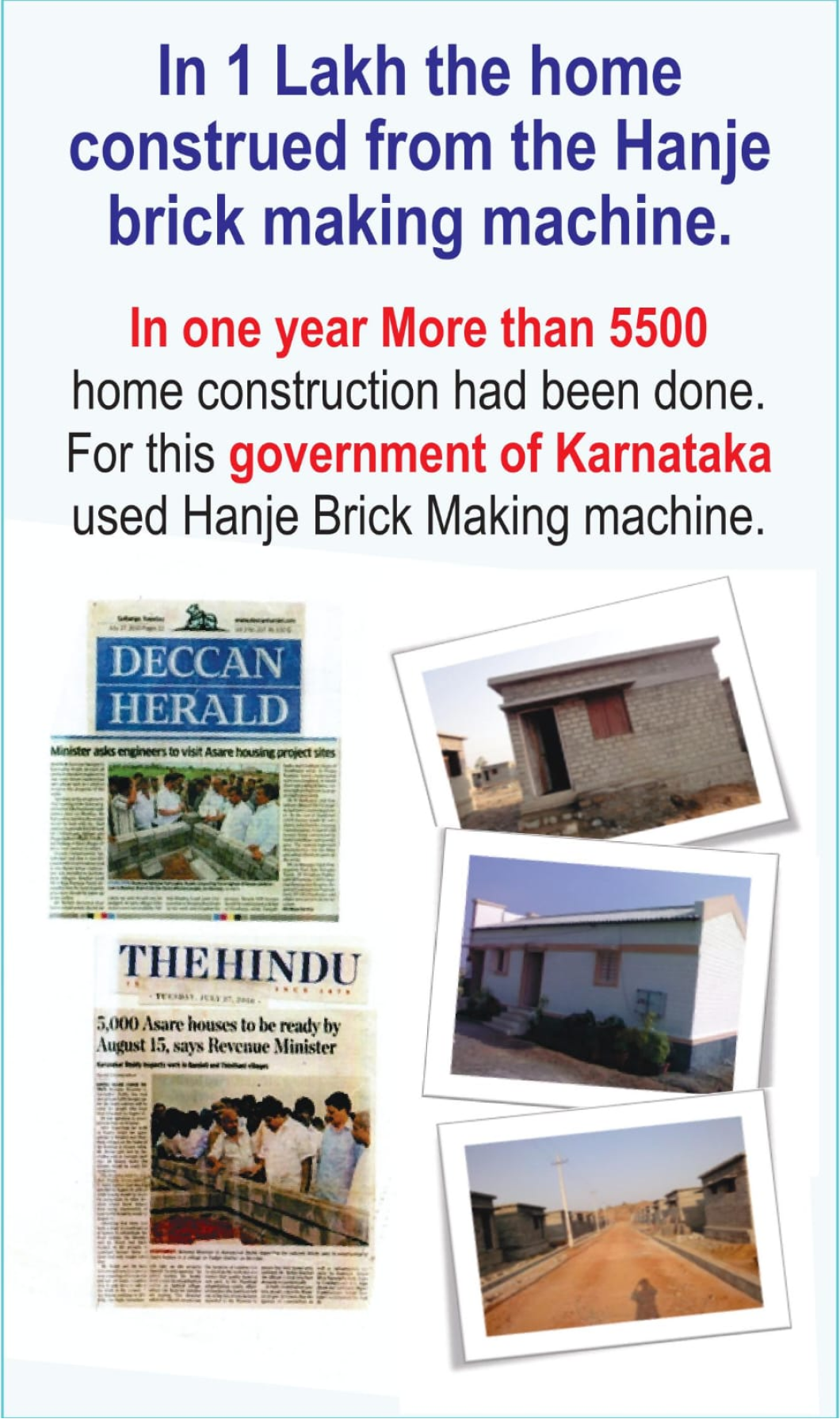

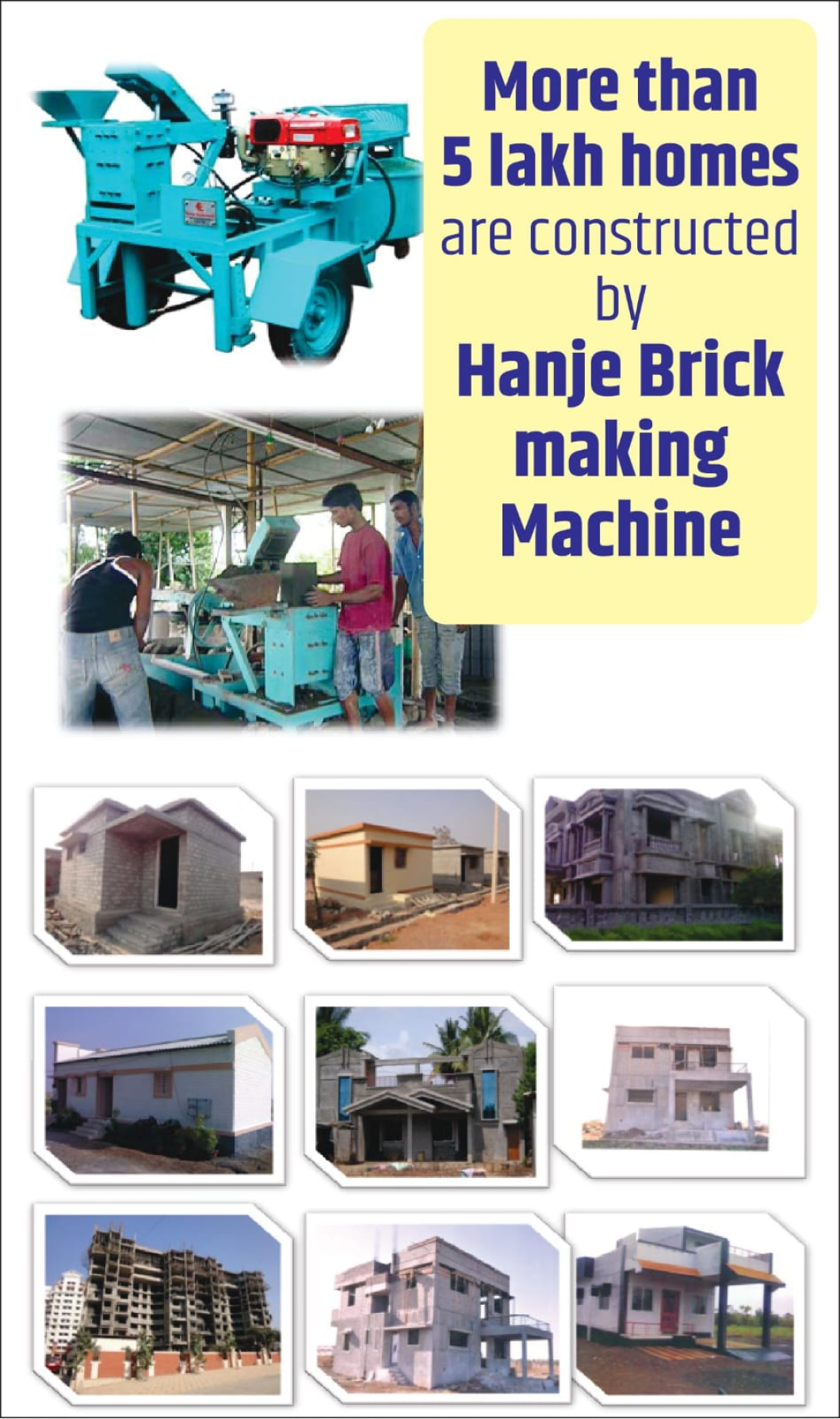

Export order cancelled - so Hanje Udyog has launch offer of Rs. 1 Lakh Discount to Indian Customer. Hanje brick machines are ready stock. These machines are offered at a price of 3 lakh 27 thousand rupees ( GST extra). Along with hydraulic brick machine and pan mixer. These machine are at ⅓ of the price of china made brick machines. 25 types of bricks can be produced in this machine by changing different moulds. Apart from this pavers blocks are also prouduced in these machines.brick machine and pan mixer are mounted on single chasis and this machine can be transported anywhere with help of tractor or jeep. Hanje udyog has been manufacturing brick machines for last 20 years and we helped to setup 3 thousand industries till date. These machines are easy to operate. Even 100 % women can operate these machines. These machines can produce up to 4 thousand brick per day. The finished brick can load by hand. These machines can run on 3 phase electricity / single phase electricity / diesel engine. There is a 3 year warranty for this machine. Minmum 2 or max. 5 unskilled laborers are required. The raw matearial are fly ash, stone dust or soil + cement required, lime can be used instead of cement. 3”x4”x9” bricks weigts from 1 kg 900 gm to 3 kg.

Brick is a heart of house construction. House can not be construct without brick. When a wall constructing a mixture of sand and cement has filling in between two bricks A wall making by structuring bricks on one another After completing a wall, the coating work will be done by a mixture of sand and cement.

Now we can eject these things easily.The 'Interlocking Bricks' are created for cheap and best construction in the world. Now this technique is using in 40 countries in the world. There is edge bar to every brick, therefore, if you place brick on one another the wall will stand. In between bricks the mixture of cement and sand to be not fulfill for us. When we manufacture the brick, by giving 10 thousand to 15 thousand Kg.Hydraulic pressure the over all part of the brick makes to be plain and polishing. Therefore we do not make to be coating At the same time making corner edge to be flat to the brick, construction seems to be get up. In this brick construction saves sand and cement, similarly reduces construction salary and construction completes so fast.

Worlds cheap and best home construction Technique towerds you now...

We have seeing the construction made by soil in Egypt since 2000 B.C. At the beginning of 19th century, the bricks manufacturing by press technique method by confirming the properties of soil and absorption capacity of water was started in Europe: In 1950, the technique of hand molded sundried bricks were developed in Housing Research Programme, in Colombia After 1950 their practical was made in Europe. South America, Russia countries.

In related time, from 1960, started research about Interlocking Bricks in Thailand, Malaysia and Philippines Thailand Institute of Scientific and Technical Research (TISTR) Bangkok, developed the technique of creating bricks by soil and cement First theoretical based house of interlocking bricks in 1984 was constructed by The Asian Institute of Technology and TISTR Hence the interlocking bricks introduced to world and these bricks have been making favourite.

By using top most level technique, from 1986 to 1990 Post Graduate Centre Human Settlement of Catholic University of Belgium construction goes fast produced interlocking bricks.

Today, in India, it seems to be the bricks transporting to the big cities But this brick manufacturing machine price is 10 to 12 lacs, hence in small Cities and small industrialists can not move towards brick production industry. By taking this fact in mind, by making new and new tests, as cheaper and cheaper to small industrialists, in possibility lowest price we manufactured Brick Production Machine.

| Warranty | 3 Years |

- Bricks construction without cement and sand :- In the manufacture of interlocking bricks we used the technique using in more than 40 countries in the world. We made brick of 9" and 8" width from our special shape attaching and fixing one in another Therefore, could not use cement and sand at the time of constructing.

- No Coating (Polishing) The bricks we made are under hydraulic pressure Each brick is plain polished when producing in machine. It is not applicable to polishing

- Best Design When each brick produced under pressure, the design is sketching By constructing the wall it seems to be specially designed Building construction gets-up Similarly, same time by labours carelessness the wall seems not to be plained. this will be missing.

- Use of the complete landBy we made brick of width 6",all land would be used. For 1 brass construction, thereboiler slug, burned brick pieces, steel slug should be totally 20 kg of cement and 10 tubs sand only as compered to 9" wall, this room form cement, lime, building materials which burned in big in size.

- Again and again UseThese bricks may use again and again in construction therefore our investment never waste.

- • By special shape the brick attach one in another strongly

- • There is no use of cement and sand for construction

- • There is not applicable to make coating (polishing)

- • The construction goes fast.

- • Best quality bricks are produced

- • Bricks are produced in low cost.

- • There unskilled labours can operate the machine.

- • The bricks are applicable to first level earthquake area.

- • The fat corner of each brick seems to be decent

- • The width is double the height, thereby autobalance.

- • Environment will be clean.

- • The bricks will be manufactured at the building construction place

- • The brick could not make to be burn as soil brick

- • There is easy to construct

- • These bricks never break

- • Construction cost reduces

- • Again and again bricks are useful

The rough material for manufacturing bricks

Soil, stone dust. fly ash, bottom ash,foundry, waste sand, waste limestone exhaustedby sugar factory, paper factory, waste gypsum,brick firm, pith. Also, materials attached to local orhome construction land.

Similarly using 80 to 90%about 10 to 15% waste materials may produce bricks.

Fly Ash : In India the electricity produced by using 72% of coal There has been exhausting 95 million ton of ash, we use only 5% of this ash only The remained ash flows always. This ash is donated freely.

Lime: From the sugar factory, paper mill soda ash factory, similarly chemical factories, we get the unused lime. In Maharashtra, there are 140 sugar factories Many factories using lime is flowing as waste: This lime is of low price. This lime never used even today We may use that lime in the manufacture of bricks There are small and big lime projects in many districts. There is also present a waste lime in large amount

Stone Dust/Threads: We may manufacture a well shaped interlocking brick by using stone dust/thread in low cement than hallow or solid block. The large amount of stone dust falling when stone crushing in a machine, which we may use in brick manufacture

Foundry Industry In Maharashtra, there are many foundry industries. By these industries.large amount of coal is used to melt iron, steel. In this project.the coal and lime are used to melting and purifying the steel The large amount of slag exhausted by these industries. A slag means, the mixture of coal ash and limestone They are substances same as present in cement By using it we may manufacture bricks with saving large amount of cement.

Soil: Soil bricks are also be made by our machine.which would not be burn. By making a powder of best type of soil, to make bricks Where there building construction work is, there may be manufacture the bricks by using the soil of that land area, by using best technique Here, when bricks manufacture take the soil from 2 feet in the ground. Similarly, check the adhesive of soil and sand and stone amount The soil to be filter through 15 sq.cm filter There from may be use 5% cement.

Burned bricks pieces: Burned bricks pieces similarly burnt.They are one type of natural cement. Using them, bricks may be manufactured in presence of low cement This brick seems to be low weight and of the colour reddish.

Old material: Once if building falls, bricks may be produced by using rough material again. Here brick pieces, polish, soil slab rods waste products are used to be manufacture bricks again. Other than this, using much more and more cheap rated rough materials, the technique of manufacturing bricks may be modify in this mainly ash of rice grain, tile polished clay, red faeces from aluminium factory, waste soil phosphogypsum of chemical fertilizer factory. others around us so many possibilities may used to that be produce bricks. We may manufacture bricks, that we may use different formulations by our experience.

| The Main Substance of Best Of Cement | The Main Substance present in flyash | The Main Substance sent in foundry sag | |

| Lime (Cao) | 62-67 | 35 to 40 | |

| Silica (SiO) | 17-25 | 37 to 67 | 21 to 31 |

| Alumina (AO) | 3-8 | 10 to 29 | 13 to 18 |

Industrial facility In the world, wherever you go, there is a chance to place bricks industry. In the machines that we manufactured we can produce, which we want the shaped the brick by changing the dye. For this industrial job there is stock of local material, using them we manufacture and sale the bricks in the market, because of local rough materials and local selling system is present, it is not dependent of us on others. As per our investment and land. There are different sources of industries.

Buing a brick manufacturing machine In this other than pan mixer by hand mixing material you may produce bricks by making material by hand mixer There will be reduce the production of bricks. After setting with pan mixer production may be increasing.

Bricks production at the place of building construction Our machine is simplified by on diesel engine also. The production of bricks may be done by moving at the place of building construction. We can reduce 20% of debit of bricks and transportation. We can manufacture these bricks on labour charge at the place of big construction.

Production of bricks under one roof If we have land water and electricity, we may produce bricks with our unit at one place and sale in market.

Bricks sale centre Brick is applicable material for construction Where there are no bricks manufacturer, there we start the selling centres by the help of our other brick manufacturers In future, after claims the industry may start the brick production centre. sExcept this, there is chance to job work in soil brick manufacturer, tractor owner, stone crusher, transportor, constructor, educated non-labourer.

9" soil brick and 8" interlocking brick

| Soil Brick | Fly ash Brick |

| 1100 bricks including break x 5 per one -5500 | 280 bricks including break x 13 per one - 2310 |

| 3 bags cement for construction X 300 Internal & external coating (polishing)-900 | 10 Kg cement for construction x 6 - 60 |

| 3 bags cement X 300 - 900 | No coating polishing - |

| Sand 35 cubic feet - 1500 | Sand 5 cubic feet - 225 |

| Payment for polishing and - 1400 constructing work | Payment for polishing and constructing work- 700 |

| Total - 10200 | Total - 4625 |

6" soil brick and 6" interlocking brick

| Soil Brick | Fly ash Brick |

| 370 bricks including break x 9 per - 3330 | 280 bricks including bricks x 10 per - 2600 |

| 1.5 bags cement for construction x 300 Internal & external coating (polishing)-450 | 10 Kg. Cement for construction x 6 - 60 |

| 3 bags cement X 300 - 900 | No coating polishing - |

| Sand 25 cubic feet - 1125 | Sand 5 cubic feet - 225 |

| Payment for polishing and constructing work- 1200 | Payment for polishing and constructing work- 700 |

| Total - 7005 | Total - 3785 |

Measure-6"x5"x10" Interlocking Bricks

| Materials | Wt. of rough material | Rate per Kg. | Total |

| Stone dust | 6Kg 1200/Brass | 25 ps per Kg | 1.50ps |

| Fly ash | 1Kg | 80 ps per Kg | 0.80ps |

| Cement | 333 gm | 6 per Kg | 2.00ps |

| Payment | per 1 | 1.00 ps | |

| Electric Bill | 0.15ps | ||

| Dye | 0.10ps | ||

| Estimated wt of brick from 7 to 7.5Kg | Total | 5.45ps | |

Selling Price of one 6"x5"x10" brick : 9.00 ps

Production Cost : 5.45 ps

Profit : 3.55 ps

Measure-8"x5"x10" Interlocking Bricks

| Materials | Wt. of rough material | Rate per Kg. | Total |

| Stone dust | 9Kg 1200/Brass | 25 ps per Kg | 2.25ps |

| Fly ash | 15Kg | 80 ps per Kg | 1.20ps |

| Cement | 500 gm | 6 per Kg | 3.00ps |

| Payment | per 1 | 1.50 ps | |

| Electric Bill | 0.20ps | ||

| Dye | 0.15ps | ||

| Estimated wt of brick from 10 to 11Kg | Total | 8.30ps | |

Selling Price of one 8"x5"x10" brick : 12.00 ps

Production Cost : 8.30 ps

Profit : 3.70 ps